Across municipalities, rural systems, and utility districts, water and wastewater operators are facing a growing number of problems: aging infrastructure, strict budgets, increased demand, cybersecurity threats, regulatory compliance, and more.

Taking advantage of technological advancements can provide solutions to many of these pain points. Automation, or SCADA, has emerged as a game-changing solution for critical infrastructure, empowering operators to reduce overtime hours, save time managing equipment manually, and protect systems from both physical and cyber threats.

As a matter of fact, incorporating automation into a water system can lead to a 25 percent reduction in maintenance costs, 20 percent fewer overtime hours, and a 14 percent initial return on investment.

To see those results and operate at peak performance, you’ll want to ensure your automation is running as efficiently as possible. Here is a full list of SCADA best practices.

SCADA Set-up

To start, a solid knowledge of your facility’s basic operations, equipment, and inventory can ensure your Supervisory Control and Data Acquisition (SCADA) system is set up correctly. This includes becoming familiar with the control narrative your SCADA system is utilizing to determine how your automation will operate.

You will also want to do an equipment audit (this could be with your engineers or your automation company’s technicians) to ensure your current equipment will satisfy your automation needs, or if any additional pieces need to be purchased for optimal performance.

Monitoring and Control

Many automation and SCADA systems allow for remote monitoring and control. Operators can utilize these technologies to monitor and control several pieces of equipment such as pumps, valves, chemical dosage, tank levels, and more. To optimize performance within monitoring and control capabilities, operators can:

- Ensure set points are accurate on these pieces of equipment to warranty standards

- Check access to on-site and remote control for vendors and operators

- Update alert/alarm settings (adjust every so often to avoid burnout or becoming “deaf” these alarms

Automating setpoints and alarm notifications reduces human error and frees up operators to focus on more critical tasks.

Data and Analytics

Data from automated systems allows for proactive-decision-making, minimizing downtime and potentially costly  repairs. To ensure you’re getting the most out of your automation system,

repairs. To ensure you’re getting the most out of your automation system,

- Confirm data gathering process with all users- whether manually or via the software

- Consistently review data to proactively monitor for unexpected changes or potential issues like cavitation or a slow leak before a line break

- Make data-driven decisions to adjust equipment or set points using trends or forecasting

Operational Oversight

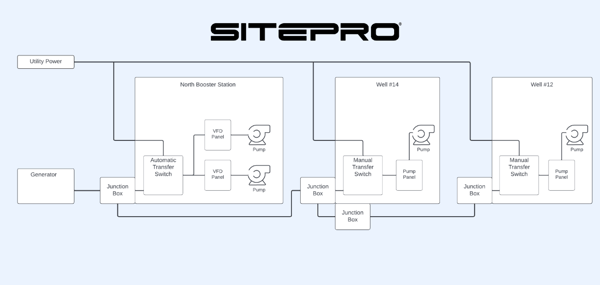

Power outages can strike at any time, especially if there is a natural disaster or electrical failure. Ensure your automation system stays online and your equipment can continue functioning in an emergency by utilizing a back-up power system, like a generator.

READ MORE: FAQ: What Happens to My SCADA System if the Power Goes Out?

While many SCADA systems provide remote monitoring capabilities so you can always keep an eye on how your equipment is operating, there’s nothing like your own two eyes when it comes to ensuring everything is operating properly. Be sure to give your system a manual check once in a while too!

By automating some “routine” tasks, operators are free to focus on higher-level projects and decision-making. Not only does automation technology improve the overall performance of the water and wastewater systems, it helps operators themselves become more efficient.

Security

Cyber attacks against water and wastewater systems and other critical infrastructure is a growing concern in the United States according to the Federal Bureau of Investigation (FBI) and Cybersecurity and Infrastructure Security Agency (CISA). However, there are ways users can protect their automation systems from these attacks.

- Incorporate multi-factor authentication

- Update operating system to the latest version

- Use strong passwords to protect remote access

- Subscribe to alerts about potential threats

- Consider paid upgrades to security

- Utilize surveillance systems

SitePro’s no-code platform lets users easily create and adjust setpoints on equipment. And users can easily set and receive alerts directly to their phone and/or email when those thresholds are exceeded or something is operating outside of its set boundaries.

SitePro’s robust data and analytics platform allows users to utilize both real-time and historical data to make proactive decisions and understand how their infrastructure has been operating over time. Not only does this encourage optimal operations for the present, but combats aging infrastructure by ensuring equipment is operating safely and correctly.

Our award-winning security system also works hand-in-hand with operators to prevent malicious cybersecurity attacks. SitePro’s software is constantly updating on its own, so you do not have to worry about having the latest upgrade. Furthermore, we offer a surveillance system that syncs up with your automation so you can physically see what’s happening at your operations at any time, from anywhere.

We understand the unique challenges and demands water and wastewater operators face, and are proud to partner with cities to embrace automation best practices.